- Basic Safety Stock Formula. This short version of a safety stock formula takes the number of products sold per day and multiplies it by the number of days' worth of ...

- Standard Deviation Safety Stock Formula. This safety stock formula is helpful when dealing with multiple uncertain variables. It is expressed as Z × σLT × D avg.

- Average – Max Safety Stock Formula. This formula is best suited for short lead times, as it doesn't take long-lead-time variables into account.

- Safety Stock with Variable Demand Formula. The safety stock with variable demand formula is best for situations where the lead time is reliable, but the demand varies.

- Safety Stock with a Variable Lead Time. As before, "Z" represents the desired service level and "σLT" represents the lead time deviation (see the standard deviation formula for more information ...

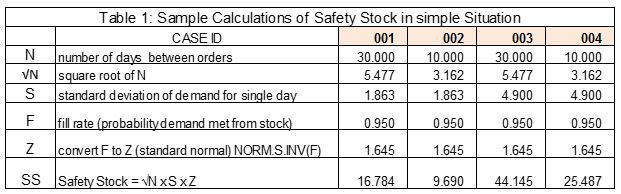

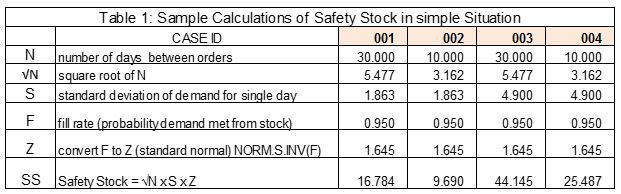

How to calculate safety stock?

Safety Stock = Z * sqrt {(Average Lead Time * (Standard Deviation in Demand) ² + (Average Sale * Lead Time Standard Deviation) ²} This formula takes into account variations in demand and supply. Step by Step Calculation Example

What is the difference between safety stock and supply stock?

Stock to protect against variation in Supply or demand (only in case demand is bigger that the forecast) Stock maintained to provide a required customer service level. Safety stock can be maintained on finished goods level, but also at component / raw material level.

What distribution method should you use for safety stock?

For businesses that experience a great deal of uncertainty, we recommend method 5, normal distribution with uncertainty on-demand and independent lead time. It’s useful in this scenario because it factors in both lead time uncertainty and sales uncertainty. Safety stock management is a critical part of being a retailer and a manufacturer.

What is safety stock and how can it improve inventory management?

Safety stock acts as a buffer amount that accounts for uncertainties such as: Safety stock mitigates the risks and consequences of stockouts, allowing your supply chain to proceed as usual even after cycle stock runs out. How Can Safety Stock Improve Inventory Management?

What is safety stock in supply chain?

According to the APICS Dictionary, safety stock is inventory that is carried to protect against forecast errors, as well as fluctuations in demand or supply.

What is safety stock in EOQ?

Safety stock definition is – Every retailer stocks inventory according to its customer's average demand. Now, sometimes there can be a rush of sales.

How do you calculate safety stock from a normal distribution?

Use the safety stock formula So, if a company's chosen service level is 90% (or 1.28), the standard deviation of their lead time is 16.6 days and their average demand is 150 units of inventory, the equation would read: 1.28 x 16.6 x 150 = 3,187 units of safety stock.

What is safety stock example?

Examples of Safety Stock Suppose a company has a team to research the market demand, and it has estimated that the demand for an umbrella is nearly one thousand units every month. As a precaution, the company can decide to have one hundred units as safety stock because the demand is never constant.

How do you calculate safety stock in Excel?

By directly using the demand standard variation formula in Excel, we get a demand standard deviation of 141.4 pieces per month. The average lead time is 1.15 months. To get the safety stock quantity, we need to multiply the service factor Z by the demand standard deviation σ and the square root of the lead time L.

How do you calculate maximum and minimum of safety stock?

To calculate safety stock, work out your average daily use for a product and multiply it by its average lead time – how long it takes, in days, to arrive once you place an order. Then subtract this number from your maximum daily use times your maximum lead time. The result is the safety stock number for that product.

How do you calculate monthly safety stock?

Safety stock = Z-score x standard deviation of lead time x average demand. For example, if aiming for a Z-score of 1.65, with average demand constant at 20 units per month, and lead times over a six month period being 2, 1.5, 2.3, 1.9, 2.1, and 2.8 months, then Safety Stock = 1.65 x . 43 x 20 = 14.3 units.

How do you calculate stock?

You'll need the original purchase price and the current value of your stock in order to make the calculation. Subtract the total purchase price from the current price of the stock then divide that by the original purchase price and multiply that figure by 100. This gives you the total percentage change.

What is the Safety Stock Formula?

In order to prevent a stockout, organizations carry additional stock, known as safety stock.

Calculating Safety Stock Using the Formula

Multiply the maximum daily usage of a part/product by its maximum lead time.

Coronavirus and the Safety Stock Formula

Unfortunately, it’s unlikely your safety stock will protect your business against large-scale global disasters, such as the coronavirus. To tackle a pandemic like this, businesses are having to rely on robust and flexible supply chains and solid contingency strategies.

What Is Safety Stock?

Stock inventory usually consists of cycle stocks, or the inventory that is expected to be sold within a given period, and safety stock. Safety stock acts as a buffer amount that accounts for uncertainties such as:

How Can Safety Stock Improve Inventory Management?

Effective inventory management relies on the cushion that safety stock provides. Tracking current stock levels accurately while considering present and future market conditions and accounting for supply lead times is just the start of effective inventory control.

Why Do Businesses Need Safety Stock?

Running out of stock is an expensive issue for businesses across the globe. Stockouts result in $984 billion worth of lost sales worldwide, with North American companies alone losing $144.9 billion, according to a study by IHL Group.

How to Calculate Safety Stock

Safety stock is about more than just having a few extra units available. Different formulas help inventory managers determine how much safety stock they need and calculate some critical variables.

Complementary Formulas

These equations provide additional information to supplement safety stock calculations. They can be used to ensure that each aspect relating to safety stock is accounted for.

Common Safety Stock Challenges & Risks

Safety stock is a valuable tool to combat stockouts, but it can have some disadvantages. There are a few factors inventory managers need to consider when developing safety stock strategies.

Safety Stock Examples

Here's how safety stock works in practice: A snow shovel manufacturer knows that demand is low during the warmer months but can fluctuate significantly in the winter depending on several hard-to-predict aspects of the weather.

What is safety stock?

Safety stock is a certain amount of extra inventory that stores and manufacturers hold in case customer demand suddenly increases. Safety stock gives companies the ability to meet customer demands while countering the risks of losing profits.

Why is a safety stock formula important?

Calculating safety stock through a formula is important because it can allow companies to make more accurate estimations regarding how much extra inventory they need to purchase to meet sudden demand increases.

How to calculate safety stock

Here is a five-step process you can follow to better understand this equation and how to use it:

Examples of safety stock calculations

Here are a few examples you can review to help you better understand safety stock calculations:

What is safety stock?

Safety Stock is defined as the additional quantities of goods stored as a safety net above the required amount to prevent going out of stock due to emergencies. An example of emergency is when sold off goods undergo damage on their way to be delivered. In such a case, safety stock can be used to ensure that the customer receives ...

Why are stocks bought and stored during good harvests?

During good harvests, stocks are bought and stored to keep prevent prices from falling below price levels or a target range, while stocks are released during harvests to prevent prices from rising above price levels or a target range. read more. and is obtained above the normal forecasted level.

What is a 95% service level?

A 95% service level means that there may be a stockout in 5% of the cases. A high service level increases the business’s cost to avoid stockout, but many firms do it nonetheless.

How to calculate lead time?

#1 – Average – Max Method 1 Max sales = the day with the highest number of items sold. 2 Average sales = average daily sales 3 Lead time = in this contest, the lead time is the time period from the point a business places an order to restock its supplies until the supplier actually delivers them. 4 The lead time is calculated in terms of days. 5 Max lead time = the maximum number of days taken by the supplier to deliver the stock since placing its order.

How to calculate safety stock?

When determining the appropriate level of safety stock, it's important to first find the standard deviation before proceeding with the calculations to determine the exact variations in supply and demand.#N#To calculate the standard deviation, follow these four steps-#N#1. Calculate the average of a set of data.#N#2. Find the sum of the average and the data from the set .#N#3. Take that total and divide it by the sample proportion to get the variance figure.#N#4 . Add the variance to the average.#N#Once this calculation is completed, it can be applied to the formula for calculating safety stock, which can be expressed as-#N#Z x sLT x D avg#N#Where Z refers to the desired service level, sLT refers to the standard deviation of lead time, and D avg refers to the demand average.#N#Calculating the optimal volume of safety stock is easy to understand once all of the figures are in place and can be done in four steps.

Why is it important to have safety stock?

There is a delicate and fine balance that needs to be struck when managing supply - carrying too little inventory can cause delays in customers not receiving their products and carrying too much inventory takes up precious storage space and increases carrying costs.#N#That's why it's important for managers to consider storing safety stock to help mitigate the effects of fluctuating consumer demand. Safety stock refers to holding an extra layer of stock to offset any sudden surges in demand. Having this extra inventory helps to reduce the risk of this product becoming out of stock.

When managing inventory control, there can be uncertainty around levels of supply and demand?

When managing inventory control, there can be uncertainty around levels of supply and demand. This is why it is important to use formulas that are more dynamic and aren't very fixed to certain figures.

What is service level?

The service level is a figure that attempts to represent the desired probability of not experiencing a stockout. The higher this service level figure is, the more safety stock is needed to be held in inventory to prevent the risk of running out. The constantly changing nature of supply and demand can make it difficult to predict the correct level of safety stock necessary to meet the demands of customers.#N#For example, let's say we're determining the safety stock of N95 medical masks. While the typical retail industry average for service level stands around 90%, these masks are more high priority so a 95% service level is used. These service level percentages represent the probability of avoiding a stockout and is expressed as a service factor. Using the chart below, we can see that a 95% service level equates to a service factor figure of 1.64.

What is safety stock?

Safety stock is defined as inventory that is carried to prevent stock outs and back order situations. Stock outs stem from factors such as fluctuating customer demand, forecast inaccuracy, and variability in supplier lead times. Many companies look at their own demand fluctuations and assume that there is not enough consistency to predict future ...

What happens if you don't carry enough inventory?

If you carry too much inventory, you tie up money in working capital; if you don’t carry enough inventory, you face stock outs and reduced service levels. There must be a balance between inventory costs and customer service.

Which approach uses mathematical theories of probability?

The mathematical approach, which uses mathematical theories of probability, imposes order and regularity on aggregates of more or less disparate elements. Different statistical calculations are presented in literature and they will provide better results than the fixed and time-based safety stock calculations.

What is the purpose of safety stock?

Its purpose is to prevent disruptions in manufacturing or customer deliveries. Stock maintained to provide a required customer service level. Safety stock can be maintained on finished goods level, but also at component / raw material level.

Why do we need safety stock?

Why safety stock is needed: 1 Stock to protect against variation in Supply or demand (only in case demand is bigger that the forecast) 2 Its purpose is to prevent disruptions in manufacturing or customer deliveries 3 Stock maintained to provide a required customer service level. 4 Safety stock can be maintained on finished goods level, but also at component / raw material level.

What is lead time in inventory?

Lead time is the amount of time from the point at which you determine the need to order to the point at which the inventory is on hand and available for use. It should include supplier or manufacturing lead time, time to initiate the purchase order or work order including approval steps, time to notify the supplier, and the time to process through receiving and any inspection operations.

Balancing service level and tied-up cash: a strategic trade-off

In case of stockout, the service level declines because the customers must, at best, wait for the product to be available again, or, at worst, make their purchase from a competitor. The service level is therefore naturally linked to the company’s inventory management.

The importance of differentiating your safety stocks by product category

Depending on how often products are sold and used, and how important they are to your business, not all of them will require the same inventory coverage strategy.

Choosing Colibri to evaluate the ideal inventory level

Colibri is a new generation Demand and Supply Planning solution that helps you find the ideal inventory level for each product reference. With the tool’s FLOW module you can isolate items and groups of items according to their sales behavior and apply specific safety stock strategies.